Benefits of Dye-Sublimation Printing

Dye-sublimation printing on fabric graphics is a fast growing technology.

By Kelly Braden

on April 8th, 2015

As one of the first and largest producers of dye-sublimation fabric graphics in the Northwest region, DisplayStar is proud to be able to offer this latest, and fastest growing, technology to our customers.

However, if you are not familiar with dye-sub printing, we would like to take this opportunity to answer a question that might be on your mind.

What are the Benefits of Dye-Sublimation Printing?

Dye-Sub Defined

Using state-of-the-art, Mamaki dye-sub printers, our signature printing process applies heat and pressure to permanently infuse graphics and fabric. The result is a seamless merge of both vibrant color and detailed texture that can be as large as 100 inches wide by 200 feet long, or even larger with a seam.

High Resolution, Photographic Quality

In addition to the sharp contrast produced by high resolution 1080 dpi, dye-sublimation printing yields the most accurate skin tones. This high resolution is your best resource for reproducing the fine detail and complex tones of any photographic image.

Infinite Applications

Tradeshow display graphic panels, event graphics, retail graphics, silicon edge graphics, light boxes, flags & banners, table throws.

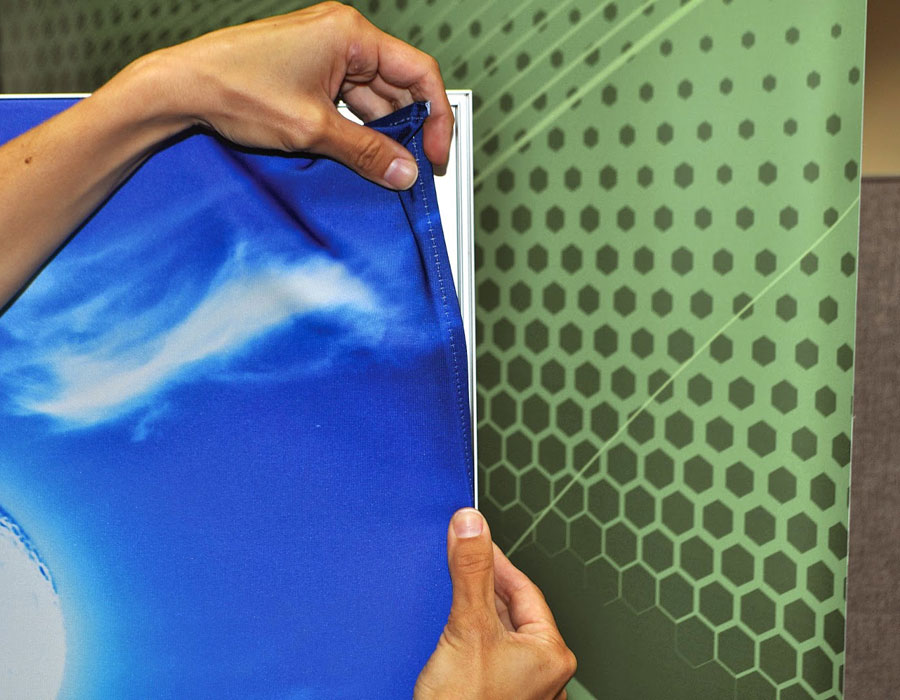

Easy to Change-Out

Along with near limitless sizes available, the wrinkle-free fabric stretches easily over display hardware making it easy to interchange and add additional graphics. Optional silicon edging seats into frames and makes for a drum-tight fit.

Easy to Ship & Store

Fabric graphics are super lightweight, making them ideal for transporting or shipping. Simply roll or fold. No more expensive shipping of flat, heavy crates. Even better, fabric graphics store in a fraction of the space so you’re more likely to keep it around and reuse them.

High Quality Fabric You Can Wash Repeatedly.

In addition to being competitively priced, all of our fabrics are highly durable, machine washable and weatherproof.

We partner with renowned textile mills to develop and produce the latest in fabrics such as:

- Soft Knit

- Flag Fabric

- Super Stretch

- Tri-Fab

- Heavy Bannerstand

We also offer a multitude of finishing options such as hemming, Velcro, silicon edge graphics (SEG), and pole pockets.

Friendly to the Environment

Dye-sublimation printing is one of the most eco-friendly printing processes today. The process does not require the use of any solvents or toxins and the fabric itself is comprised mainly of recycled, post-consumer materials.

Made in Beaverton, Oregon

All dye-sub graphics are printed and sewn in-house in our production facility.